Nutrient timing is the practice of matching fertilizer strength and composition to what the plant needs at each stage of growth. When EC, pH, and N‑P‑K balance are adjusted in step with vegetative growth, stretch, bulking, and ripening, cultivators see more consistent yields, tighter quality distributions, and fewer nutrition‑related problems. Front Row Ag’s A/B/Bloom system and feed charts make this stage‑based approach repeatable at scale, with typical programs running between 1.6-2.6 EC (standard), 1.8-3.0 EC (high strength) and a rootzone pH of 5.6–6.0. By treating nutrition as a schedule instead of a static recipe, growers can turn their fertilizer program into a reliable lever for both yield and quality.

Introduction: From “Static Recipe” to Stage‑Based Feeding

Many facilities still run a “set and forget” fertilizer program: one EC target, a single ratio, and minimal adjustments over the life of the crop. The result is familiar and vigorous veg followed by unpredictable stretch, inconsistent bud density between rooms, and quality that drifts from run to run.

In reality, the plant’s nutrient demand changes quickly across the cycle. Early veg is about building structure; weeks 1–3 of flower are about stretch and flower site formation; mid‑flower is about packing weight; and the last weeks are about finishing without stacking excess salts. A nutrition program that doesn’t shift with those phases is always playing catch‑up.

Nutrient timing solves this by treating fertilizer as a schedule, not just a formula. With Front Row Ag, that means using A/B/Bloom, plus tools like Triologic, PhosZyme, and Front Row Si, in a way that lines up with your veg, stretch/stacking, bulking, and ripening windows. When timing is consistent, EC and pH stay in control, and lab results stop being a surprise.

Shop Front Row Ag 3-2-2 Commercial Bundle (A/B/Bloom)

Common Bottlenecks in Nutrient Schedules

Running One Recipe All Cycle

A single “all‑purpose” recipe seems simple, but it rarely fits all stages of growth:

- In early veg, plants may be underfed, building weak stems and limited leaf area.

- In late flower, the same recipe can oversupply nitrogen and total salts, delaying maturity and creating overly leafy flowers.

This mismatch often shows up as lanky stretch, uneven bud set, or late‑stage tip burn and fade that’s hard to interpret.

EC That Doesn’t Match Growth Rate

The plant’s mineral demand is highest when it’s growing fastest, during veg and the first three weeks of flower, and lower as growth slows toward harvest. Many facilities either:

- Run too low EC early, limiting biomass and root development, or

- Run too high EC late, causing substrate EC to climb and increasing the risk of lockout.

Most Front Row Ag programs perform best between 2.0–2.6 EC (standard), 2.4-4.0 EC (high strength) , with higher values (high strength) early in the cycle and a controlled taper as plants finish. Flat EC across the cycle wastes control you already have.

pH Drift Outside the Uptake Window

Even with the right EC, pH that lives outside the ideal band can quietly undermine nutrient timing. Above about pH 6.0 in a high‑EC solution, the risk of precipitation and micronutrient unavailability increases sharply. Below ~5.5, root stress and certain toxicities become more likely.

When pH drifts without correction, growers may misdiagnose issues as “strain quirks” instead of a simple solubility problem.

Unclear Roles for Supplements

Biologicals and enzymes are powerful tools when they’re used for their intended purpose:

- Triologic is a microbial root inoculant designed to boost root health and nutrient cycling by promoting beneficial rhizobacteria and mycorrhizae instead of a trace element supplement.

- PhosZyme is an enzyme‑based product that helps unlock phosphorus and improve nutrient efficiency at very low usage rates.

- BioFlo is an irrigation line cleaner that removes biofilm and mineral buildup.

When these tools are mispositioned, growers either don’t see their full benefit or introduce unnecessary complexity into the feed program.

How Front Row Ag’s Approach Solves It

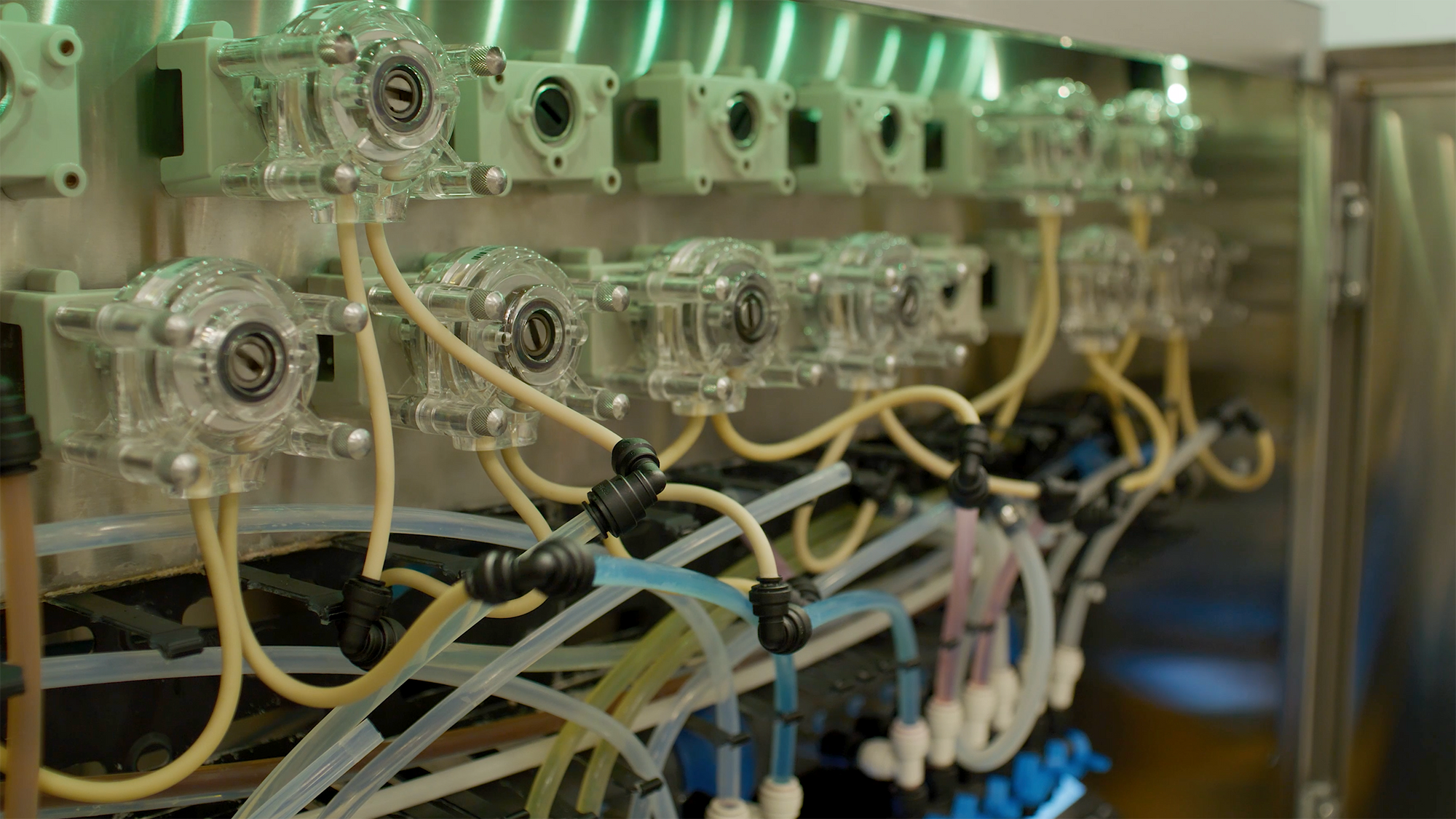

Front Row Ag is built around a modular 3‑part base (Part A, Part B, and Bloom) plus a small set of targeted tools (Front Row Si, Triologic, PhosZyme, BioFlo). Together with the Direct‑to‑Reservoir (DTR) and Stock Concentrate (3‑2‑2 and 4‑3‑3) feed charts, they give cultivators a consistent way to implement nutrient timing across rooms, strains, and facilities.

A/B/Bloom: Stage‑Based N‑P‑K and Ca/Mg

- Part A and Part B supply the bulk of nitrogen, calcium, magnesium, and micronutrients at balanced ratios, eliminating the need for separate cal‑mag in most situations.

- Bloom layers in additional phosphorus and potassium as plants move into stretch, stacking, and bulking, so early veg isn’t overloaded with bloom minerals, and late flower receives the support it needs.

Standard DTR and 3‑2‑2 Stock Concentrate feed charts express this as a sequence of recipes (Veg, Stretch, Stack, Swell, Ripen) with total EC typically ranging from ~2.6–3.0 EC early down to ~1.6–2.0 EC in the final weeks, depending on whether you’re running standard or high‑strength programs.

Front Row Si: Structural Support and Stress Buffer

Front Row Si delivers monosilicic acid (MSA), an immediately available form of silicon that strengthens cell walls, supports stress tolerance, and improves water and nutrient balance.

Key points:

- Used either as a root‑zone input (low ml/gal in feed) or foliar spray (0.5–2 ml/gal, 3–5 applications over the first ~5 weeks).

- Always mixed first into clean water before A/B/Bloom when using a DTR approach.

Triologic: Root Inoculant for Nutrient Efficiency

Triologic is a concentrated blend of plant growth‑promoting rhizobacteria that:

- Enhances mycorrhizal colonization

- Fixes nitrogen and cycles essential nutrients like phosphorus and potassium into plant‑available forms

- Improves stress tolerance and overall root health

It’s typically applied at 1–2 ml/gal once per week, especially effective when introduced early (clones, transplants) and continued through veg and early flower.

PhosZyme: Enzyme‑Driven Phosphorus Availability

PhosZyme is an enzymatic biostimulant used at very low rates and often injected with Part B in stock‑concentrate setups. It:

- Enhances root growth and nutrient uptake

- Helps liberate phosphorus from chemical bonds, improving P efficiency in solution

- Has almost undetectable fertilizer contribution—its value is in enzyme activity, not added N‑P‑K

BioFlo: Keeping Irrigation Uniform

BioFlo is a bio‑enzyme line cleaner that removes biofilm and mineral buildup in irrigation lines, emitters, and reservoirs.

- Used at ~30 ml/gal as needed to soak and flush systems, not as a continuous nutrient additive.

- A clean system ensures that the timing and EC you design at the tank match what actually reaches each plant.

By combining these tools with clear feed charts, growers can move from “artful guessing” to a defined program where each phase has a specific target and role for each product.

Principles for System‑Driven Nutrient Timing

Align Feeding with Growth Phases

Front Row Ag’s guidance breaks the cycle into stages that align with both plant physiology and the feed charts:

-

Vegetative (14–21 days)

- Objective: Build root mass, stem strength, and canopy.

- Emphasis: Higher nitrogen and calcium, moderate magnesium, modest phosphorus.

- Typical range: Standard programs around 2.0–2.6 EC, high‑strength up to ~3.0 EC, pH 5.6–6.0.

-

Stretch / Stacking (Flower Weeks 1–3)

- Objective: Manage elongation while setting and stacking flower sites.

- Emphasis: Maintain strong N and Ca support while introducing more Bloom to raise P/K and support energy transfer and cell division.

- Typical range: 2.4–3.0 EC, maintaining the higher end of your program during rapid growth.

-

Bulking / Swell (Flower Weeks 4–6)

- Objective: Pack weight and density into set sites.

- Emphasis: Slightly lower nitrogen, sustained phosphorus and potassium, continued calcium and magnesium supply.

- Typical range: Taper feed EC modestly (e.g., from 1.6 EC in standard programs, or 1.8 EC in high‑strength programs) while monitoring runoff and tissue color.

-

Ripening (Flower Weeks 7–9)

- Objective: Finish flowers while avoiding unnecessary salt buildup.

- Emphasis: Lower overall EC while maintaining a balanced mineral profile.

- Typical range: Final recipes in Front Row charts sit around 1.6–2.0 EC, depending on program and cultivar response. The focus is on reduced strength, not switching to plain water.

This progression reflects how the plant’s nutrient demand peaks early and gradually decreases as growth slows.

Work Within Tight EC and pH Bands

Across these phases, most facilities see success keeping:

- Total feed EC:

- Standard programs: roughly 2.0–2.6 EC

- High‑strength programs: roughly 2.4–3.0 EC

- Rootzone pH:

- 5.6–6.0, with many growers targeting ~5.7–5.8 for fertigated systems

Within that window:

- Increase EC in small steps (0.1–0.2 EC at a time) when plants show strong growth, healthy color, and low substrate EC.

- Decrease EC when runoff climbs significantly above feed EC or when leaf tips burn and margins curl.

Maintain Consistent Mixing and Delivery

Consistency in how nutrients are mixed and delivered is just as important as the recipe itself. For direct‑to‑reservoir programs:

- Fill reservoir with RO water.

- Add Front Row Si (if used in the reservoir) and mix 3–5 minutes.

- Add Part A, mix 3–5 minutes.

- Add Part B, mix 3–5 minutes.

- Add Bloom, mix 3–5 minutes.

- Adjust pH up with Front Row pH Up in small increments, allowing 5–15 minutes between additions, targeting 5.6–5.8.

- Validate EC and pH at the emitter, not just in the tank.

In stock‑concentrate setups (3‑2‑2 or 4‑3‑3), follow the specified bag‑per‑gallon recipes, validate the concentrate strength (50 ml into 1 gallon of RO water), and pair injector ratios to hit your desired EC at the plant.

Use Data Loops Instead of Guesswork

A system‑driven program relies on measurement:

- Runoff EC and pH to see what the rootzone is experiencing.

- Substrate sensors (if available) for continuous EC and moisture trends.

- Tissue or sap tests to confirm that elemental supply matches plant demand.

Record feed EC, runoff EC, and visible symptoms by phase. Over a few runs, patterns emerge, and you can tune each stage’s recipe with confidence.

Practical Implementation Tips

Below is a simple framework for putting nutrient timing into practice with Front Row Ag.

Choose a Baseline Program

Start by deciding whether your environment and cultivars are better suited to the Standard or High Strength feed charts:

- Standard: Strong lighting and decent environmental control, but not pushing absolute maximums.

- High Strength: Very high PPFD, elevated CO₂, tight environmental control, frequent irrigation, and cultivars known to tolerate higher EC.

If you’re unsure, Standard is usually the safer starting point.

Map Your Calendar to Front Row Recipes

For a typical 9‑week flower:

- Veg (14–21 days): Run the Veg recipe at ~2.4–2.6 EC (standard) or up to ~3.0 EC (high strength).

- Flower Week 1–3 (Stretch / Stack):

- Week 1–2: Use Stretch at 2.4–2.6 EC (standard) or 3.0 EC (high).

- Week 3: Use Stack at ~2.2–2.4 EC (standard) or 2.7 EC (high).

- Flower Week 4–6 (Bulking / Swell): Use Swell around ~2.0–2.2 EC (standard) or 2.4 EC (high).

- Flower Week 7–9 (Ripen): Use Ripen around ~1.6–1.8 EC.

These numbers should be adjusted based on your substrate, irrigation frequency, and cultivar behavior, but they provide a realistic starting scaffold that aligns with Front Row’s charts.

Incorporate Supplements Intentionally

-

Front Row Si

- Rootzone: Follow Si vs EC guidance (higher Si at lower EC, reducing as EC increases).

- Foliar: 0.5–2 ml/gal, 1× per week up to day 21 of flower.

-

Triologic

- 1–2 ml/gal as a root drench, typically weekly, starting in clones or transplants and continuing through veg and early flower.

-

PhosZyme

- Inject or mix with Part B per usage guidelines. Think of it as a P‑efficiency tool, particularly useful in systems where maximizing nutrient efficiency and root performance is critical.

-

BioFlo

- Use as needed at ~30 ml/gal to soak and clean irrigation lines and reservoirs between crop cycles or during scheduled line maintenance—not as a daily additive in plant feed.

Diagnose and Adjust with Specific Steps

Instead of “add more nitrogen,” use small, defined adjustments:

-

Early flower pale leaves (no tip burn, low runoff EC):

- Increase total feed EC by 0.2, maintaining part ratios (all parts increased equally).

- Recheck runoff EC after 2–3 irrigation events.

-

Tip burn or clawing, runoff EC > 0.5 above feed EC:

- Reduce feed EC by 0.2 and/or increase runoff percentage for a few irrigations.

- Confirm pH is still between 5.6–6.0.

-

Uneven development between tables with identical feed:

- Check distribution: emitter flow, line cleanliness, and reservoir mixing. BioFlo soaks and proper reservoir cleaning often solve “nutrient” issues that are really irrigation problems.

Over time, the goal is to have a defined playbook for each common symptom by phase, linked to specific EC, pH, and irrigation changes.

FAQs

What’s a practical fertilizer schedule for hydroponics using Front Row Ag?

Use a stage‑based schedule:

- Veg (14–21 days): Higher nitrogen and calcium with the Veg recipe at ~2.4–2.6 EC (standard) or up to ~3.0 EC (high).

- Stretch / Stack (Flower Weeks 1–3): Keep EC on the higher end of your range while introducing Bloom per the Stretch and Stack recipes to support rapid growth and flower site formation.

- Swell / Bulking (Weeks 4–6): Gradually taper EC (for example, from 2.4 down to 2.0 EC in standard programs) as growth rate slows, keeping Bloom in line with the feed chart.

- Ripen (Weeks 7–9): Finish with balanced nutrition at a lower EC (roughly 1.6–2.0), instead of switching to only water.

Maintain a rootzone pH of 5.6–6.0 throughout, checking pH as close to the crop as possible.

Should silica be added before or after nutrients?

Silica should always be diluted first in clean water before adding other concentrates. With Front Row Ag, that means: Front Row Si → Part A → Part B → Bloom → pH adjustment. This order helps avoid precipitation and keeps all components fully soluble.

How do feeding needs vary between cultivars?

Different cultivars will “choose” different spots within the 2.0–3.0 EC band:

- Some respond best on the lower end of the range with slightly gentler EC ramps.

- Others perform better at the higher end, especially in high‑light, high‑CO₂ environments.

Rather than relying on labels like “indica” or “sativa,” treat each cultivar as its own profile:

- Start with the standard feed chart.

- Track feed EC, runoff EC, and visual response by phase.

- For heavy feeders, step EC up in 0.1–0.2 increments; for lighter feeders, favor the lower end of the range.

Over a few runs, this builds a cultivar‑specific playbook without changing the underlying system.

How does nutrient timing affect terpenes and cannabinoids?

When nitrogen is tapered appropriately in mid‑ to late flower and potassium and sulfur remain available, the plant can shift energy from new vegetative growth toward secondary metabolites, including terpenes and cannabinoids. A well‑timed program:

- Avoids late‑stage excessive nitrogen that keeps pushing leaf growth.

- Maintains balanced K, Ca, Mg, and micronutrients so the plant can sustain resin production through ripening.

Paired with stable environmental conditions, stage‑based nutrition helps keep potency and aroma within tighter, more predictable ranges across harvests.

Do I need to flush with plain water at the end?

Front Row Ag’s guidance focuses on controlled EC tapering, not extended plain‑water flushes:

- Use the Ripen recipe at reduced EC to match the plant’s lower mineral demand while maintaining balanced nutrition.

- Manage runoff and substrate EC to avoid salt accumulation, rather than trying to “reset” the medium with long flushes of plain water.

This approach maintains plant health and quality without the downsides of stripping nutrients completely at the finish.

Conclusion

Nutrient timing is the process of making your fertilizer program follow the plant’s growth curve instead of fighting against it. By aligning EC, pH, and N‑P‑K balance with veg, stretch/stacking, bulking, and ripening, cultivators can stabilize growth, reduce guesswork, and narrow the variability in yield and lab results from run to run.

Front Row Ag’s A/B/Bloom system, combined with Si, Triologic, PhosZyme, and BioFlo, is designed to make this timing practical at any scale. The feed charts provide a proven backbone; EC and pH targets keep the chemistry on track; and consistent mixing and maintenance ensure uniform delivery to every plant.

When nutrient timing becomes a system instead of a series of ad‑hoc adjustments, each harvest becomes a repeatable outcome rather than a one‑off success.