Professional crop quality requires more than just high nitrogen levels. Peak genetic expression in specialty produce depends on moving beyond the basic building blocks to master the relationship between sulfur and secondary minerals. Internal tissue data and field results show that balanced micronutrient ratios and sulfur-rich nutrition are major contributors to aromatic intensity and plant resilience in high-value crops.

High Yield, Flat Quality: The Invisible Ceiling

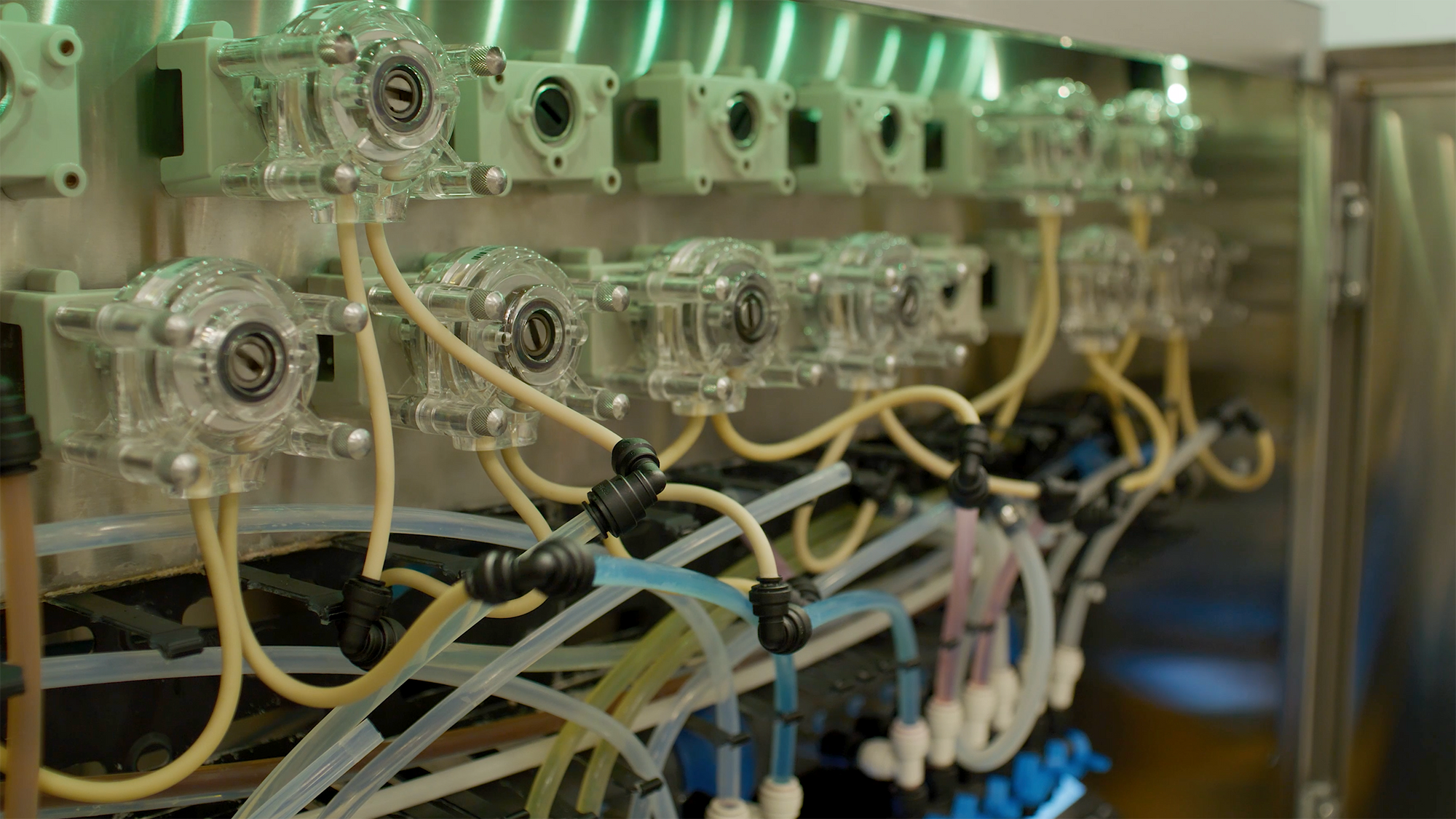

Imagine a commercial facility where every technological variable is perfectly dialed in. The high-intensity LED lighting is pushing the upper limits of what the plants can process. The CO₂ levels are elevated to match the light intensity, and the primary nutrient numbers are exactly where the books say they should be. The plants look healthy, the stems are thick, and the biomass is heavy, but something is wrong. The final product feels flat. The vibrant colors that usually define the specialty cultivar are dull, and the deep, complex aromatic profiles are almost entirely absent.

This is a common nightmare for lead growers, and it is often referred to as hitting the invisible ceiling. This ceiling is created by a metabolic throttle. Just like a high-performance racing engine needs more than just high-octane gasoline to run at top speed, specialty cultivars need a precise blend of secondary elements to complete their complex biological processes. When sulfur levels are low or when a minor micronutrient is out of balance, the plant is forced to prioritize basic survival over the production of premium oils and pigments.

The plant essentially keeps its foot on the brake because it lacks the specific chemical tools needed to accelerate into high-quality production. Physiological principles show that this bottleneck usually happens because the plant cannot finish its protein synthesis. Protein synthesis is a complex operation that requires every gear to be in place. If you think of nitrogen as the bricks of the plant house, sulfur and micronutrients are the mortar and the specialized plumbing. Without them, you can have all the bricks in the world, but you will never be able to build a functional masterpiece.

The Spark Plug of the Plant: How Sulfur Nutrient Benefits Drive Genetic Potential

To understand the science of quality, we must look at how sulfur nutrient benefits act as the spark plug for the plant’s internal factory. Sulfur is a core component of two essential amino acids: cysteine and methionine. These amino acids are the starting point for almost every protein and enzyme the plant creates. If sulfur is lacking, protein production slows down. This causes a ripple effect throughout the entire life cycle, leading to stunted development that growers often misidentify as a nitrogen deficiency.

Beyond just building proteins, sulfur is the foundation of secondary metabolite cultivation. These metabolites are the compounds that give specialty crops their unique market value, such as essential oils, resins, and defensive terpenes. When a plant has an abundance of available sulfur, it can produce a compound called glutathione. This acts as a powerful internal antioxidant. It serves as a biological shield, allowing the high-value crop to handle the high-energy environment of a modern commercial grow room without suffering from internal oxidative stress.

Micronutrients like iron and manganese play a supporting role in this enzymatic engine. Iron is essential for the production of chlorophyll, which acts like the solar panels of the plant. Manganese helps with the splitting of water molecules during photosynthesis. When these elements are delivered in the correct plant physiology context, the plant metabolism runs at peak efficiency. This allows the crop to divert energy away from basic maintenance and toward the production of the complex chemical compounds that determine the final quality of the harvest.

Traffic Jams on the Nutrient Highway: The Risk of Poor Micronutrient Balancing

One of the most common operational bottlenecks in large-scale facilities is a lack of precision in micronutrient balancing. In an effort to push plants harder, some growers over-apply individual supplements. This often leads to a phenomenon known as mineral lockout. You can visualize the plant’s internal transport system as a nutrient highway. If you send too many large semi-trucks, like calcium, down the road at once, they take up all the lanes. This prevents the smaller cars, which represent the micronutrients, from reaching their destination.

For example, many facilities struggle with over-applying calcium in the hopes of strengthening plant structure. However, the data indicates that excessive calcium can inadvertently lock out magnesium and boron. This creates a traffic jam where the plant is literally starving for a specific tool even though the reservoir is full of it. The result is a crop that shows mysterious deficiencies despite a very high feed EC.

Guesswork in a commercial setting is a recipe for financial loss. Consider a facility that failed to account for the mineral content in their starting water. They added a standard micronutrient package on top of source water that already had high levels of carbonates. This caused the pH to swing wildly, making the iron and zinc in their mix fall out of solution and become solid grit. By the time the growers noticed the yellowing leaves, the plants had already lost ten days of momentum. Front Row’s cloning strategies highlight the need for early stability to avoid these late-cycle crashes, because momentum lost in the first two weeks is difficult to recover later.

Engineering Predictability: Precision Micronutrient Ratios Hydroponics in the Front Row Ag System

The Front Row Ag commercial system is designed to remove the guesswork by maintaining a perfectly balanced mineral profile from start to finish. The data from the feed charts shows how the A/B/Bloom system manages these complex relationships automatically. Part A, which is a 14-0-8 formula, serves as the primary micronutrient carrier. It contains a robust package of chelated iron and manganese. Because these minerals are chelated, they stay protected and available to the plant even if the environment is not perfect.

The nutrient system lens reveals how different recipes support different phases. For instance, the High Strength DTR chart targets an EC of 3.0 during the Stretch phase. This high concentration ensures that as the plant rapidly expands its vegetative structure, it has an immediate and dense supply of micronutrients to build new chlorophyll cells. It also supports the high metabolic demand of rapid vertical growth. To ensure these small parts are delivered accurately, facility managers often utilize the 3-2-2 Stock Concentrate method to maintain consistency at scale.

Sulfur is strategically managed through Part B and the Bloom part. These contain high concentrations of magnesium sulfate and potassium sulfate. By following the feed chart, the grower provides a steady increase in sulfur during the Swell phase, where the EC is typically set around 2.4. This timing is critical because the Swell phase is when the plant begins to shift its energy into essential oil production. Maintaining a solution pH in the mid–5s (typically around 5.6–5.8 at application) is vital here, as this is the range where the sulfur and micronutrient ratios of hydroponics are most soluble and easily absorbed by the root hairs.

Precision Tactics: Best Practices for Maintaining the Metabolic Throttle

Implementing a data-driven mineral program requires more than just mixing the right bags. It requires a commitment to a few universal principles of agricultural chemistry that ensure the nutrient highway remains clear.

Follow the Recommended Mixing Order

The mixing instructions are very specific: when mixing Direct-to-Reservoir with RO water, always follow Front Row’s prescribed order—add Part A first and mix 3 to 5 minutes, then Part B, then PhosZyme, followed by Bloom, and finally make any pH adjustments with pH Up. This order maximizes solubility, protects micronutrients, and minimizes precipitation risk. Front Row Si is typically used as a foliar product or through its own stock and injector following the Si vs. EC guidance. If you integrate silica into solution, keep it in a separate stock or follow manufacturer guidance instead of dropping it directly into a fully built batch, as adding concentrated silica or other non-organic additives into a partially mixed, high-pH solution can encourage micronutrients to form precipitates.

Validate Your System with Contributed EC

Every facility manager should know exactly what each part of their fertilizer contributes to the total EC. For example, Part A contributes 0.322 EC for every gram per gallon added. If your feed chart calls for 5.3 grams per gallon of Part A to reach a target of 1.7 EC, and your sensors show something different, you know immediately that your injection skids need calibration or your batch was not mixed correctly. Monitoring your contributed EC ensures your plant is receiving the exact ratio of micronutrients intended.

Prioritize RO Water Quality

All feed charts are based on using reverse osmosis water with a starting EC of 0.0. Using city or well water introduces unknown minerals that can disrupt the delicate micronutrient balancing. Water quality varies greatly by region, so starting with a blank canvas is the only way to ensure that the final mineral ratios at the dripper match the engineering of the formula.

Monitor the Sulfur Taper

As you move into the final stages of the life cycle, the feed chart shows a reduction in total EC, often dropping from 2.4 down to 1.8 in the Ripen phase. This reduction helps clear the substrate of excess salts while the specific ratios in the Ripen recipe ensure that sulfur remains high enough to finish the production of secondary metabolites without the interference of high nitrogen. Utilizing the Bloom component correctly during these transitions is the key to a clean finish.

Sulfur and Micronutrient Management FAQ

My feed chart says Part A should contribute 2.0 EC during the Stretch phase, but my meter is reading 2.3 total EC. Does this mean my plants are getting too many micronutrients?

The feed chart values for Part A, Part B, and Bloom are listed as contributed EC. This means the amount of salt that specific part adds to pure water. If your total reading is higher than the sum of the parts on the chart, you must first check your starting water. Most often, the extra 0.3 EC is coming from minerals already present in your water source. Micronutrients must be measured accurately to avoid toxicity. If you are using RO water, a reading that is significantly higher suggests that your injection rates are incorrect or your stock tanks were not mixed to the proper ratios. Always validate your stock tanks against the 3-2-2 or 4-3-3 validation charts provided in the guide.

I want to increase the aroma of my specialty produce. Can I add a sulfur-based bloom booster to the Swell recipe?

The Bloom and Part B components are already formulated with high levels of sulfur from potassium sulfate and magnesium sulfate. Adding an outside sulfur booster can easily upset the micronutrient ratios hydroponics that we have carefully balanced. When you add extra sulfur from an unknown source, you risk increasing the acidity too much or creating a mineral antagonism that could lock out calcium. The data indicates that the most effective way to increase aromatics is to maintain a consistent environment and follow the Swell and Ripen recipes exactly as written.

The feed chart suggests a slightly acidic root-zone. What happens to my micronutrients if my reservoir drifts up to 6.5?

Maintaining a stable rhizosphere is critical because pH acts as the gatekeeper for nutrient uptake. Front Row typically targets a slightly acidic solution, often in the 5.6–5.8 range at application. As the pH rises above about 6.3, many micronutrients like iron, manganese, and zinc begin to form solid particles and settle at the bottom of the tank. Once they have fallen out of solution, the plant can no longer absorb them. This is why we recommend adjusting pH carefully and always checking pH near the emitters to keep it in range. This ensures that the metabolic throttle remains wide open and your plants have full access to the complete spectrum of minerals.

Conclusion: Predicting Excellence Through Data

In a competitive market, precision is the only way to ensure long-term profitability. By moving away from anecdotal tips and focusing on the physiological principles of sulfur and micronutrients, facility managers can turn crop quality from a lucky accident into a repeatable business process.

When you manage the metabolic throttle with a balanced system, you provide your specialty crops with the tools they need to express their true genetic potential. The ROI of this data-driven approach is found in every harvest through deeper aromas, more vibrant colors, and a resilient crop that can withstand the demands of a high-intensity commercial environment. Excellence is not a mystery. It is the result of engineering, predictability, and a deep respect for the chemistry of plant life.

To optimize your facility and start seeing predictable results, apply for a Commercial Account today.