Introduction

This article focuses on the role of clean water in Controlled Environment Agriculture (CEA). Clean water is essential for preventing irrigation system problems and plant diseases caused by pathogens like Pythium, Phytophthora, and Fusarium. These can come from various sources, including water supplies, tanks, biofilms, and filters.

We'll explore how issues arise from seasonal changes, temperature shifts, and poor filter maintenance. Our goal is effective pathogen risk reduction, not total sterilization. We'll examine disinfection methods like UV light, ozone, peroxides, hypochlorous acid, and chlorine compounds like Calcium Hypochlorite.

You'll learn about monitoring water cleanliness through Chlorine PPM and ORP levels. By the end, you'll know how to maintain high-quality water for healthy CEA crops.

Why Water Cleanliness is Essential

In CEA, water cleanliness is not just a bonus; it's a necessity. Here's why:

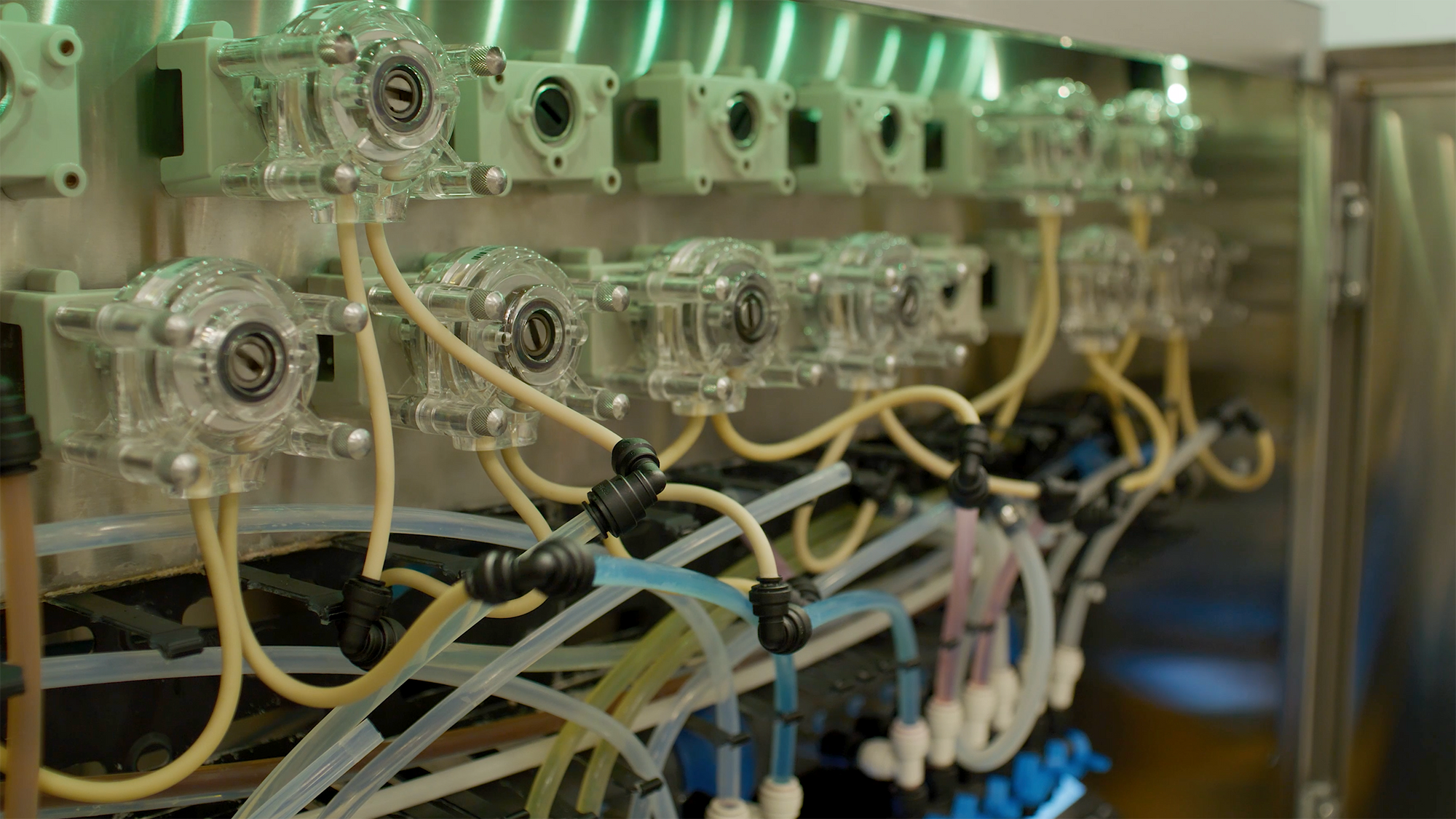

- Preventing Irrigation Disruptions: Dirty water can lead to clogs and biofilm formation in irrigation systems. Algae is also problematic as an indirect contributor to substrate and pest problems. These issues disrupt water flow and nutrient delivery, hindering plant growth.

- Avoiding Pathogen Transmission: Water is a common pathway for plant diseases. Pathogens like Pythium, Phytophthora, and Fusarium thrive in contaminated water and can quickly spread across your CEA system, affecting plant health.

-

Sources of Contamination:

- Water Source: Natural water sources can introduce pathogens.

- Water Holding Tanks: Stagnant water can become a breeding ground for pathogens.

- Biofilm in Pipes: Accumulated biofilm is a habitat for harmful microbes.

- Surfaces, Injectors, Mixing Chambers, and Filters: Dirty surfaces and filters can harbor and spread pathogens. Fertigation equipment contains many areas that are easily inhabited by pathogenic microbes, leading to continuous reintroduction of those microbes downstream of the contamination site.

- Air: Many microbes that colonize tanks, lines, and fertigation equipment exist in the air with the potential to opportunistically colonize water system components.

Understanding these risks is the first step in implementing effective sanitation measures to maintain the health and productivity of your CEA crops.

How Things Go Wrong: The Challenges in Water Quality Management

Maintaining water quality in CEA irrigation systems can be challenging due to various factors:

- Seasonal Changes: Different seasons bring different challenges. For example, warmer temperatures in summer can increase pathogen activity and growth, while colder temperatures in winter can affect water chemistry and plant resistance.

- Temperature Swings: Sudden temperature changes can stress plants, making them more susceptible to diseases. These fluctuations can also impact the effectiveness of disinfection methods and alter water chemistry.

- Filter Maintenance: Filters play a crucial role in keeping water clean. Neglected or poorly maintained filters become less effective over time, allowing pathogens and debris to pass through, which can lead to system-wide contamination.

The Goals of Disinfection in CEA Systems

Disinfection in CEA aims not to sterilize but to control risks effectively:

- Minimizing Pathogen Risk: The primary goal is to reduce the presence of harmful pathogens to levels that do not threaten plant health. Complete eradication is often unnecessary and impractical.

- Maintaining System Efficiency: By controlling biofilm and clogs, disinfection helps maintain efficient water and nutrient flow, ensuring plants receive what they need for optimal growth.

- Balancing Chemicals: Disinfection involves managing chemical levels to avoid harming plants while controlling pathogens. It's a delicate balance that requires careful monitoring and adjustment.

Considerations for Choosing Disinfection Methods

When selecting a disinfection method for CEA water systems, consider these factors:

- Cost: Evaluate the initial setup costs and ongoing expenses. Some methods require more investment upfront but save money in the long run.

- Flexibility: Consider how adaptable the method is to changes in your system, such as scaling up or dealing with varying water quality.

- Impact on Plants: Some methods might be more suitable for certain crops. It's important to understand how each method affects plant health and growth.

- Ease of Use and Maintenance: Assess how user-friendly and maintenance-intensive each method is. This affects the overall workload and efficiency of your operation.

Disinfection methods

Ultraviolet (UV) Light Disinfection

Ultraviolet (UV) light disinfection is a non-chemical process that neutralizes a wide range of pathogens, including bacteria, viruses, and fungi, by damaging their DNA. Its effectiveness largely depends on the water's clarity, as turbid water can shield microorganisms from UV exposure. The design of the UV system is crucial, needing to balance factors like flow rate and lamp intensity to ensure all water is adequately exposed. While UV disinfection is efficient, leaving no chemical residues and acting rapidly, it requires regular maintenance, such as cleaning the lamps and replacing them periodically. One significant limitation is the lack of residual disinfection; water can be re-contaminated post-treatment if it encounters pathogens again.

Non-Chlorine Based Oxidation Agents

Ozone Disinfection

Ozone disinfection in irrigation systems utilizes ozone (O3), a powerful oxidizing agent, to eliminate pathogens and contaminants. Ozone is generated on-site and infused into the water, where it rapidly reacts with pollutants, breaking them down into less harmful substances. The process effectively inactivates a wide range of microorganisms, including bacteria, viruses, and fungi. One of the key benefits of ozone is its ability to decompose back into oxygen, leaving no toxic residues in the water. However, the system requires careful handling due to the reactive nature of ozone; it’s easy to damage plant roots through excessive ozone concentration. It can be more costly to set up and operate compared to other methods and requires precise control to avoid plant damage.

Hydrogen Peroxide Disinfection

Hydrogen Peroxide compounds such as Zerotol are another popular non-chlorine oxidizing agent used in CEA systems. Zerotol, a stabilized hydrogen peroxide solution, acts by releasing reactive oxygen species that target and destroy pathogens. It's effective against a broad spectrum of pathogens and is relatively easy to dose and apply. One significant advantage is that it breaks down into water and oxygen, making it environmentally friendly. However, the interaction between peroxides and micronutrients/metals in the feed solution is one of the most consistent causes of reservoir turbidity; the peroxides oxidize some of the metals leading to “haziness” in the reservoir and increasing the difficulty of cleaning.

Chlorine Compounds

Sodium Hypochlorite (NaOCl)

Commonly available as liquid bleach, sodium hypochlorite is a widely used disinfectant in CEA systems. When added to water, it produces hypochlorous acid (HOCl) and the hypochlorite ion, which are responsible for its sanitizing properties. The balance between these two chemicals is determined by the water's pH, with hypochlorous acid being more effective as a sanitizer. Sodium hypochlorite is effective against a broad range of pathogens and helps in controlling algae and biofilm in the irrigation system but is a subpar choice in CEA systems as it is difficult to avoid sodium toxicity, especially for sodium-sensitive crops.

Hypochlorous Acid (HOCl)

Hypochlorous acid is the active sanitizing agent produced when either sodium or calcium hypochlorite is added to water. It is highly effective at a pH range of 6-7.5, making it a potent disinfectant against a wide array of pathogens. HOCl works through oxidation, disrupting the cellular structures of microbes. Its effectiveness as a sanitizer is significantly higher than that of the hypochlorite ion, especially in the lower pH range.

Calcium Hypochlorite (Ca(ClO)2)

Calcium hypochlorite, often used in solid form, shares similar disinfecting principles to sodium hypochlorite. Upon dissolution in water, it too generates hypochlorous acid and hypochlorite ion. It is effective against various pathogens and is useful in controlling algae and biofilm. Like NaOCl and HOCl, it works through oxidation of organic material including microbes. Calcium hypochlorite has a higher chlorine content (~65%) and longer shelf life compared to liquid bleach (NaOCl). It is especially beneficial in larger systems due to its high concentration, shelf life, and low cost. The effectiveness of hypochlorous acid as a disinfectant in water systems hinges on maintaining the correct pH balance to maximize its concentration relative to the hypochlorite ion.

Recommended Use of Calcium Hypochlorite in CEA Systems

Why Calcium Hypochlorite?

Calcium hypochlorite is an excellent choice for CEA water disinfection due to its cost-effectiveness, ease of use, and flexibility. Its high chlorine concentration, makes it economical for large-scale operations. Its solid form ensures a longer shelf life and easier storage compared to liquid alternatives. Critically, calcium hypochlorite's ability to effectively control a wide range of pathogens, algae, and biofilms makes it a versatile tool for maintaining water quality in diverse CEA setups.

Maintaining Calcium Hypochlorite Effectiveness

To maximize the effectiveness of calcium hypochlorite, certain factors must be managed:

- Storage Conditions: Proper storage is crucial to preserve its potency. It should be kept in a cool, dry place, away from direct sunlight and organic materials to prevent degradation and unsafe reactions. When mixed in stock solution, the container should be sealed to the air.

- Water pH Management: The effectiveness of calcium hypochlorite largely depends on the pH of the water. It works best in a slightly acidic to neutral pH range (<6.5 pH), where hypochlorous acid, the more potent sanitizing form, predominates.

Applied Chlorine, Chlorine Demand, and Residual Chlorine

Understanding the relationship between applied chlorine, chlorine demand, and residual chlorine is key to effective water treatment:

- Applied Chlorine: This is the initial chlorine ppm (supplied by calcium hypochlorite) added to the water. It needs to be sufficient to meet the system's chlorine demand.

- Chlorine Demand: This represents the quantity of chlorine consumed to oxidize all organic and inorganic materials in the water, including pathogens and contaminants. Factors like water source, temperature, and the presence of biofilm can influence chlorine demand.

- Residual Chlorine at the Dripper: It's the concentration of chlorine remaining in the water after it has satisfied the system's chlorine demand. This residual chlorine is what provides ongoing protection as the water travels through the irrigation system. Monitoring and maintaining an appropriate level of residual chlorine at the dripper ensures effective ongoing disinfection while minimizing the risk of plant toxicity.

Monitoring Water Cleanliness: Chlorine PPM and ORP

Chlorine PPM (Parts Per Million)

Monitoring chlorine concentration in parts per million (PPM) is a direct method to ensure water disinfection is performing adequately. Maintaining the correct chlorine PPM is essential for pathogen control while preventing phytotoxicity. Chlorine meters or color test kits can be used to measure free chlorine levels, which indicate the amount of disinfecting agent available after the chlorine demand has been met. For most fertigation systems, a residual free chlorine level between 0.5 to 2 PPM at the farthest point from injection is often sufficient for sanitization without harming plants. These levels need to be checked regularly as fluctuations in water source, temperature, and system use can alter chlorine demand and residual levels.

Oxidation-Reduction Potential (ORP)

Oxidation-Reduction Potential (ORP) is a measure of the water's ability to break down contaminants, reflecting the overall sanitizing power of the water. ORP readings are taken in millivolts (mV) and higher readings typically indicate greater disinfection potential. For fertigation systems, an ORP level of 300-500 mV is generally considered adequate for effective pathogen control. ORP is an indirect measure that can be influenced by pH, temperature, and the presence of other oxidizing or reducing substances in the water. Therefore, it should be used in conjunction with PPM measurements for a more complete assessment of water cleanliness. ORP sensors provide real-time data, allowing for continuous monitoring and adjustments as needed to maintain proper sanitization levels.

Note that chlorine ppm and ORP don’t scale linearly; the ORP of a given chlorine ppm is highly dependent on the pH (and thus the ratios of hypochlorous acid to hypochlorite ion) in the irrigation water.

Key Recommendations for Using Calcium Hypochlorite in CEA

In conclusion, our key usage recommendations for maintaining water cleanliness with Calcium Hypochlorite are centered on its significant benefits:

- Pathogen Suppression: Calcium Hypochlorite effectively suppresses a wide range of pathogens, ensuring the health of your CEA crops.

- Maintenance of Irrigation System Function: Regular use prevents the buildup of biofilm and turbidity, thus keeping emitters and filters free from clogs.

- Clean Water Storage and Fertilizer Injection: Ideal for use in reverse osmosis (RO) or clean water storage systems and can be injected along with fertilizers to maintain a sanitary nutrient solution.

For the precise application:

- Monitoring at the Dripper: Keep a consistent eye on ORP and Chlorine levels at the dripper. Aim for ORP within the 300-500 mV range and maintain a free chlorine level of around 2 PPM. Adjust as necessary, taking into account the changes in chlorine demand which can be influenced by a variety of factors including water source, temperature, and crop type. Note that in a facility with varying lengths of irrigation runs, the shorter ones may have higher chlorine ppm at the dripper and adjust accordingly.

- Stock Solution Mixing Ratios: Mix stock solutions at either 20g per gallon or 3g per gallon, matching the injection rate of your dosing equipment to ensure the proper disinfectant levels.

In terms of best practices for handling stock solutions:

- pH Management: Keep the pH of stock solutions at or below 6.5 to optimize the efficacy of the chlorine.

- Storage Conditions: Store stock solutions in sealed containers to avoid contamination and degradation.

- Protection from Light and Heat: Keep the stock solution away from light and heat, which can accelerate the decomposition of the chlorine compound.

- Freshness: Replace stock solutions every 7-14 days to ensure the highest level of activity and to prevent the potential for diminished efficacy due to degradation over time.

The following table outlines the application rates, stock concentrations, and injector settings for a variety of facility needs:

Test Your Knowledge

CEA Water Cleanliness Competency Test

-

Why is it crucial to maintain clean water in CEA systems?

- A) To enhance the color of the plants.

- B) To reduce the need for nutrients.

- C) To increase the water's pH level.

- D) To prevent irrigation problems and suppress pathogens.

-

Which of the following is a common source of water contamination in CEA?

- A) Water pumps

- B) LED lights

- C) Biofilm in pipes

- D) Plant containers

-

What is a potential problem associated with using hydrogen peroxide-based disinfection methods?

- A) They can increase water hardness.

- B) They can react with metal ions, causing turbidity in the feed water.

- C) They can attract insects to the system.

- D) They can lower the oxygen levels in the water.

-

For large-scale CEA, which disinfection method is generally most suitable?

- A) Calcium hypochlorite treatment

- B) Manual removal of contaminants

- C) Ultrasonic cleaning

- D) Hand-wiping with isopropyl alcohol

-

What is the difference between chlorine applied, demand, and residual?

- A) Applied is the amount used, demand is the amount stored, and residual is the amount lost.

- B) Applied is the initial concentration, demand is how much the plants use, and residual is what remains in the soil.

- C) Applied is the initial amount added, demand is the amount needed to react with contaminants, and residual is what's left to sanitize the water.

- D) There is no difference; they are interchangeable terms.

-

What is the target Oxidation-Reduction Potential (ORP) range at the dripper for continuous use in a CEA system?

- A) 50-150 mV

- B) 300-500 mV

- C) 650-750 mV

- D) 900-1100 mV

-

For continuous sanitation, what is the recommended chlorine PPM at the dripper?

- A) 0.5 PPM

- B) 1 PPM

- C) 2 PPM

- D) 5 PPM

-

When mixing stock solutions of calcium hypochlorite, what is the recommended concentration for a 0.2 - 2% injector?

- A) 3g/gal

- B) 20g/gal

- C) 50g/gal

- D) 100g/gal

-

What is a best practice when storing calcium hypochlorite stock solutions?

- A) Store in a warm place to increase solubility.

- B) Mix with organic matter to stabilize the solution.

- C) Expose to sunlight for natural UV sanitization.

- D) Store in a sealed container, protected from light and heat.

-

Why should the pH of calcium hypochlorite stock solutions be maintained at or below 6.5?

- A) To prevent the growth of algae in the stock solution.

- B) To maximize the ORP and sanitation power of the solution.

- C) To increase the water solubility of calcium hypochlorite.

- D) To enhance the color and smell of the stock solution.

2 ความคิดเห็น

Dan

Hello, do you have any information about rdwc, hydroponics? Also , do you know how much peroxide is to much and causing problems with metals and micros? Thank you!

Hello, do you have any information about rdwc, hydroponics? Also , do you know how much peroxide is to much and causing problems with metals and micros? Thank you!

Prohibition farms

This article has so much information that will definitely give us a second look at water! Not many realize how important this is.

This article has so much information that will definitely give us a second look at water! Not many realize how important this is.