Introduction

In Controlled Environment Agriculture (CEA), precise control over inputs is necessary for achieving predictable and high-quality crop production. While parameters like light, CO2, humidity, and nutrients are commonly adjusted, water temperature is a key underrated variable requiring careful management due to its wide-ranging effects.

Water temperature influences numerous processes in hydroponics, including:

- Source water treatment: Affecting filtration efficiency and RO membrane performance

- Nutrient chemistry: Impacting solubility, stability, and availability of fertilizer components

- Root-zone conditions: Directly influencing nutrient uptake, oxygen availability, and metabolism

- Microbial populations: Determining which beneficial or pathogenic organisms thrive

- Sanitation effectiveness: Altering the performance of water treatment methods

Effective water temperature management ensures consistent results for CEA cultivators. A range of 18-22°C (65-72°F) is ideal for most crops, but understanding the specific impacts allows for informed control decisions that can significantly improve system performance.

Water Temperature Impacts Across the System

Temperature affects processes throughout the water's path in a hydroponic system. Let's explore each area in detail.

Source Water & Pre-Treatment

Storage considerations are often overlooked but important. Water temperatures above 25°C (77°F) in raw water storage can promote algal and bacterial growth, potentially increasing the load on downstream filtration and sanitation systems before the water even enters your primary growing system.

Reverse Osmosis (RO) System Efficiency is highly temperature-dependent. RO membrane specifications standardize permeate flux and rejection rates at 25°C (77°F). Colder water increases viscosity, substantially reducing permeate flux, potentially by 2-3% for every 1°C (approximately 1.5% per 1°F) below the standard.

For example, this means that a nominal 10,000 GPD RO system operating with inlet water at 60°F would only produce about 7,300 gallons per day of RO, assuming other factors like pressure and feed water quality remain consistent with the rating conditions.

This reduction means that cold water requires increased membrane area or longer operating times to achieve the same output volume. On the other end of the spectrum, exceeding maximum temperature specifications can affect membrane integrity or performance over time, potentially leading to premature replacement costs.

Practical Application: Pre-Heating for Cold Source Water

Facilities with source water below 20°C (68°F) may want to pre-heat water before it reaches the RO unit to maintain design flux rates. A recommended method involves an on-demand water heater combined with a Thermostatic Mixing Valve (TMV).

A TMV automatically blends hot and cold water streams through an internal thermal element that expands or contracts in response to temperature changes, maintaining output at the target temperature regardless of pressure or temperature fluctuations in the input lines.

The heater, sized for the required flow rate (GPM/LPM) and temperature rise (ΔT = Target Temp - Min Inlet Temp), heats water above the target (e.g., 30°C/86°F). The TMV then blends this water with a cold bypass flow to deliver a stable feed, typically 25°C (77°F), to the RO unit. This TMV configuration provides greater output stability compared to relying on the heater's direct output alone. TMV valves can be found on Amazon for from any plumbing supplier. Note that for high-capacity RO systems, tankless gas heaters are going to be the most cost effective option.

Sizing calculations are required for system design to ensure adequate heating capacity.

Nutrient Management

Water temperature significantly affects how your nutrients dissolve, remain stable, and interact within the system.

Stock Solution Preparation is directly affected by temperature. Temperatures below 15°C (60°F) significantly reduce the solubility of important fertilizer salts like Calcium Nitrate, Potassium Sulfate, Magnesium Sulfate, and various phosphates. Attempting to mix concentrated stocks in cold water can result in incomplete dissolution or precipitation, leading to inaccurate nutrient concentrations and potential equipment clogging. Using water at approximately 25-30°C (77-86°F) can dramatically improve dissolution and ensure your nutrient formulations are accurately prepared.

Batch Tank Dynamics continue to be influenced by temperature after mixing. Temperature directly affects dissolution rates and can cause precipitation of nutrients if not properly managed. Cold temperatures also impede root nutrient uptake.

Conversely, temperatures above 25°C (77°F), while not directly causing precipitation, contribute to negative biological effects like reduced dissolved oxygen levels and accelerated pathogen growth, which can indirectly lead to nutrient deficiencies by impairing root function.

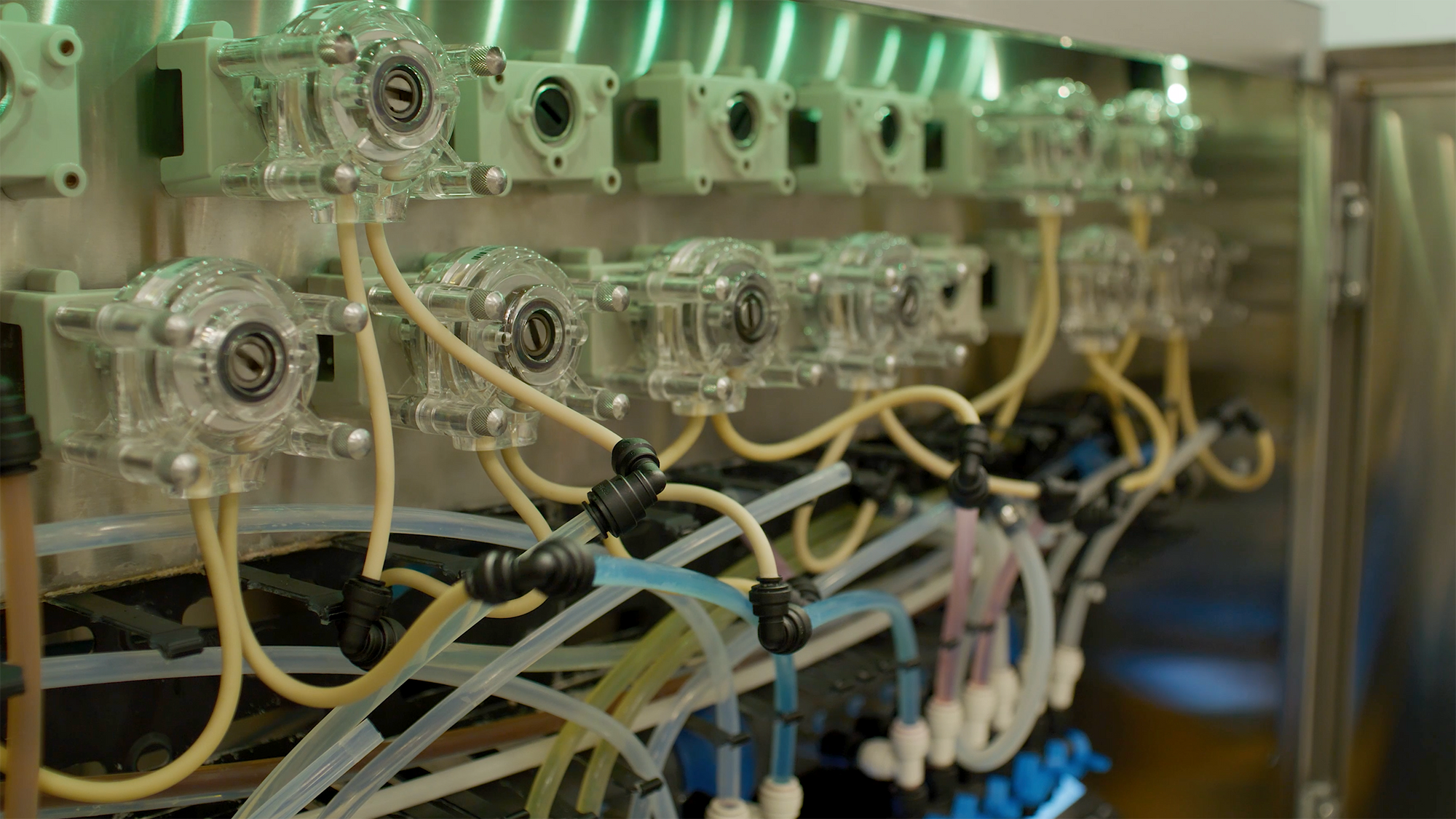

Fertigation & Injection Systems perform differently at various temperatures. Cold stock solutions exhibit increased viscosity, which can affect the accuracy of Venturi injectors and other proportional dosing systems. Additionally, injecting near-saturated stock solutions into cold irrigation lines can cause localized precipitation of less soluble components, potentially leading to emitter clogging and uneven nutrient distribution.

The Root Zone Environment

The root zone is where water temperature has its most direct impact on plant performance.

Plant Physiology responds dramatically to root temperature. Temperature influences metabolic activity throughout the root system. Low temperatures reduce root respiration rates, decrease cell membrane fluidity, and slow the enzyme kinetics governing active nutrient transport.

The uptake of several essential nutrients—phosphorus, potassium, calcium, and magnesium—is particularly sensitive to cold conditions. At the other extreme, temperatures above 27°C (80°F) induce heat stress, impair root function, and increase respiration demand without corresponding benefits.

Dissolved Oxygen (DO) capacity has an inverse relationship with temperature. Oxygen solubility in water decreases as temperature rises. At sea level, saturated DO decreases substantially with warming: approximately 11.3 mg/L at 10°C (50°F), 9.1 mg/L at 20°C (68°F), and 7.6 mg/L at 30°C (86°F).

This creates a challenging interaction: elevated temperatures simultaneously decrease oxygen-carrying capacity while increasing root and microbial oxygen consumption rates. This combination can potentially lead to hypoxic (<2 mg/L) or even anoxic (<0.5 mg/L) conditions that are highly detrimental to root health and function.

Microbial Ecology within the root zone is shaped significantly by temperature. Temperature acts as a selective pressure on the root-zone microbiome, favoring different organisms at different temperature ranges. Common pathogens like Pythium species and Fusarium oxysporum grow optimally above 24-25°C (75-77°F), particularly under low DO conditions.

In contrast, certain beneficial microbes (including Trichoderma and various Bacillus species) may perform optimally or compete more effectively within the 18-22°C (65-72°F) range. Very low temperatures suppress most microbial activity, both beneficial and harmful. Temperature management therefore becomes an important factor in influencing the microbial community composition within your growing system.

pH Stability is indirectly affected by temperature. Temperature influences the rates of chemical reactions and biological processes (including root exudation and microbial metabolism) that affect hydrogen ion concentration [H+], thereby indirectly impacting pH stability and the frequency of pH adjustments needed in the system.

Water Temperature and Sanitation Efficacy

Water temperature significantly impacts the performance of sanitation protocols commonly used in CEA operations:

Chemical Oxidizers (e.g., Hypochlorites, PAA)

General Kinetics: Temperature increases the reaction rates of chemical oxidizers. This means that warmer water typically accelerates disinfection processes, but often at the cost of stability.

Chlorine Specifics: While disinfection speed increases at higher temperatures, Free Chlorine stability decreases; it degrades and off-gasses faster, reducing effective contact time. This requires carefully balancing dose, contact time, and temperature for optimal results. Cooler temperatures (<15°C / 60°F) noticeably slow chlorine's action, potentially requiring longer contact times or higher concentrations.

Ozone (O₃)

Solubility & Stability: Ozone solubility decreases as temperature rises, while its decomposition rate (shorter half-life) increases with temperature. This creates an interesting dynamic: although reaction kinetics are faster at higher temperatures, the reduced solubility and stability mean that higher residual concentrations and effective contact times can often be more readily achieved in cooler water, potentially improving overall disinfection performance.

Temperature Management Strategies

An effective approach to water temperature management involves both comprehensive monitoring and appropriate control methods:

Monitoring

Use reliable, calibrated temperature sensors at relevant locations throughout your system for comprehensive oversight:

- Source water entry point: Establish baseline temperature and track seasonal variations

- Post-treatment locations: After RO systems and after heating/cooling equipment

- Nutrient reservoir: The central point where temperature stability is most important

- Root zone: Direct measurement of the environment plants experience

Data logging helps identify trends and verify system performance over time, allowing for proactive management rather than reactive responses to problems.

Control Methods

Temperature Control Methods:

-

Passive Approaches:

- Insulate reservoirs and pipes to reduce temperature fluctuations

- Position tanks away from direct heat sources including grow lights

- Choose light-colored reservoirs to minimize solar heat gain

- Schedule water changes during cooler periods

-

Active Heating:

- Immersion heaters for direct reservoir warming

- Inline heaters with TMVs for precise temperature control

- Heat exchangers for larger systems requiring energy efficiency

- Conditioning of irrigation room and water storage spaces as needed

-

Active Cooling:

- Dedicated hydroponics chillers sized appropriately for your system volume

- Cooling capacity (BTU/hr) calculation: Volume (gal) × ΔT (°F) × 8.34 ÷ Hours

- Geothermal loops or cooling towers for commercial-scale operations

Stability

Aim to minimize rapid temperature fluctuations (e.g., > 2-3°C / 4-5°F change within hours) to avoid stressing plants. Consistent temperatures typically yield better results than fluctuating conditions, even if those fluctuations remain within the generally acceptable range.

Conclusion

Water temperature significantly impacts CEA hydroponics by affecting water treatment efficiency, nutrient chemistry, root physiology, microbial populations, and sanitation effectiveness.

- Water treatment: Temperature directly impacts RO efficiency and filtration performance

- Nutrient dynamics: Proper temperatures ensure complete dissolution and availability of fertilizer components

- Root health: The 18-22°C (65-72°F) range optimizes metabolism and nutrient uptake for most crops

- System biology: Temperature helps select for beneficial microbes while suppressing pathogens

- Water treatment: Sanitation methods perform differently at various temperature ranges

Monitoring and active management of water temperature using appropriate heating or cooling methods are required components of system operation for optimizing plant health, resource use, system hygiene, and achieving consistent crop production outcomes.

The optimal range of 18-22°C (65-72°F) for most crops ensures that nutrient solutions—including specialized formulations like Front Row Ag's 3-part fertilizer system—perform as intended, delivering consistent results and maximizing crop potential.